- Introduction

- Production Description

- Specification

- Product Processing

- Application

- How to control quality?

Xinda is an enterprise specializing in the production of ferroalloy in Inner Mongolia. Abundant local mineral resources and electricity at favorable prices. Focus on ferroalloy industry production for more than 25 years, with rich experience. Average production and sales of 8,000 tons per month.

Production Description

Silicon slag is a by-product of silicon metal, consisting of scum that floats on the furnace during the process of smelting silicon. Its main content is silicon (40%-90%), and the rest are C, S, and P.

The price of silicon slag is lower than that of ferrosilicon. It is a good substitute for ferrosilicon in steelmaking to reduce cost.

Specification

| Silicon Slag | |||||

| Grade | Chemical Composition(%) | ||||

| Si | Al | C | S | P | |

| ≥ | ≤ | ||||

| 50 | 50 | 5 | 5 | 0.1 | 0.05 |

| 60 | 60 | 5 | 5 | 0.1 | 0.05 |

| 70 | 70 | 3 | 3.5 | 0.1 | 0.05 |

| 80 | 80 | 3 | 3.5 | 0.1 | 0.05 |

| Packing: 1mt/big bag | |||||

| Size: 0-10mm, 10-50mm, 10-100mm | |||||

Product Processing

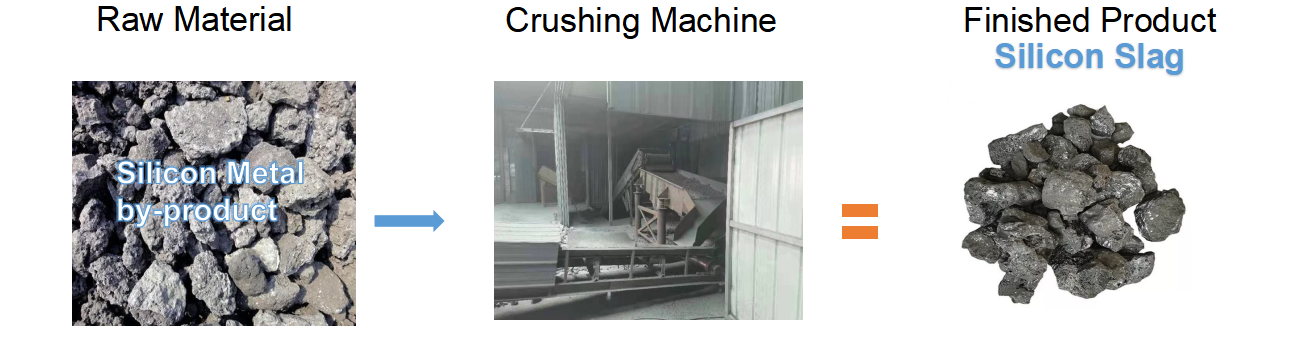

How to produce Silicon Slag?

Silicon slag is the residue left after silicon ore is refined, and the residue also contains a lot of silicon content.

Silicon Metal by-product--Broken--Finished Product Processing

Application

1. Silicon slag alloy can be used as deoxidizer to purify the process of production.

Silicon slag serves as a deoxidizer and refining agent in industrial silicon production. It is effective in desulfurization from its alkaline oxide content, which reacts with sulfur dioxide to form sulfate.

2. Silicon Slag can increase the furnace temperature.

In steelmaking, silicon slag enhances furnace temperature, thereby improving the smelting process.

3. For manufacturers, silicon slag is a cost-saving option.

As the byproduct of metal silicon, the price of silicon slag is lower than that of metal silicon. It serves as an excellent substitute for ferrosilicon in steelmaking, effectively reducing costs.

How to control quality?

Company Testing Report/ Third-Party Inspection

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

AZ

AZ

UR

UR

BN

BN

GU

GU

JW

JW

KM

KM

LO

LO

LA

LA

NE

NE

PA

PA

TA

TA

TE

TE

MY

MY

UZ

UZ

KU

KU

KY

KY

LB

LB

SD

SD