- Introduction

- Production Description

- Specification

- Product Processing

- Application

- How to control quality?

Xinda is an enterprise specializing in the production of ferroalloy in Inner Mongolia. Abundant local mineral resources and electricity at favorable prices. Focus on ferroalloy industry production for more than 25 years, with rich experience. Average production and sales of 2,000 tons per month.

Production Description

Silicon carbon alloy, also commonly known as high carbon silicon or high carbon ferro silicon, is a kind of by-product of silicon metal, it contains Si(60-70%) with C(15-25%). Silicon carbon alloy usually is used to replace ferrosilicon in steel plants.

How to get HC Silicon?

In the process of smelting metal silicon, the heating of the electrodes in the furnace is not enough. This causes the bottom of the furnace to reach the temperature required to produce metal silicon. Raw materials such as bottom silica and carbon are not fully reacted. After a long time of accumulation, high-carbon silicon is thus formed.

Specification

| Silicon Carbon Alloy | |||||

| Grade | Chemical Composition(%) | ||||

| Si | C | Al | S | P | |

| ≥ | ≤ | ||||

| Si68C18 | 68 | 18 | 3 | 0.05 | 0.05 |

| Si65C15 | 65 | 15 | 3 | 0.1 | 0.1 |

| Si60C20 | 60 | 20 | 4 | 0.1 | 0.1 |

| Packing:25kg/bag, 1mt/big bag | |||||

| Size:1-10mm, 10-50mm or according to the client's request | |||||

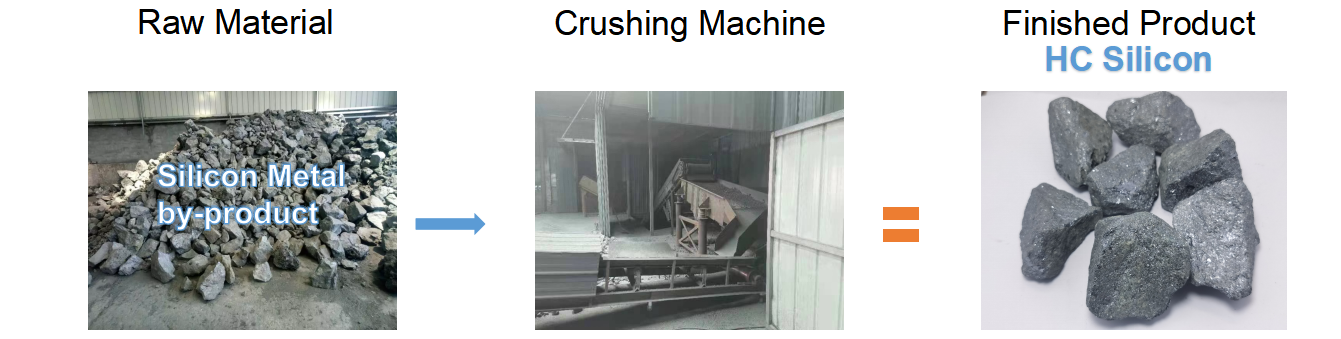

Product Processing

How to produce High Carbon Silicon?

Silicon Metal By-Product---Broken--Finished product processing

Application

1. High-carbon silicon contains silicon, usually as deoxidation to added high-carbon silicon during steelmaking.

The silicone contains interacts with oxygen to deoxidize the molten steel, thereby enhancing its hardness and quality.

The silicon element in the high carbon silicon and the oxygen have a good affinity, so molten steel still has the characteristic of not splashing after being put into it.

2. High-carbon silicon also has the advantage of slag collection.

Putting a certain proportion of high carbon silicon into the molten steel can allow the oxides in the steelmaking process to quickly clump together, which is convenient for filtration treatment, makes the molten steel pure, and greatly improves the density and hardness of the steel.

3. High-carbon silicon could increase furnace temperature.

Puttingsilicon-carbon alloy in the process of steelmaking can increase the furnace temperature, increase the conversion rate of ferroalloy, and accelerate the reaction speed of molten steel and elements.

4. High-carbon silicon could help manufacturers to save costs.

Today, ferroalloy materials are more expensive. As a new type of metallurgical material, silicon-carbon alloy is favored by many manufacturers because of its lower price than traditional metallurgical materials. Silicon carbon alloy can replace ferrosilicon, silicon carbide, recarburizer in steelmaking. Reduce the amount of deoxidizer, and be used in converter smelting deoxidation alloying process, so using silicon-carbon alloy can save manufacturers costs and increase profits.

How to control quality?

Company Testing Report/ Third-Party Inspection

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

AZ

AZ

UR

UR

BN

BN

GU

GU

JW

JW

KM

KM

LO

LO

LA

LA

NE

NE

PA

PA

TA

TA

TE

TE

MY

MY

UZ

UZ

KU

KU

KY

KY

LB

LB

SD

SD