Ferrosilicon

-

Grade: FeSi75, FeSi72, FeSi70, FeSi65

-

Packing: 1mt/big bag

-

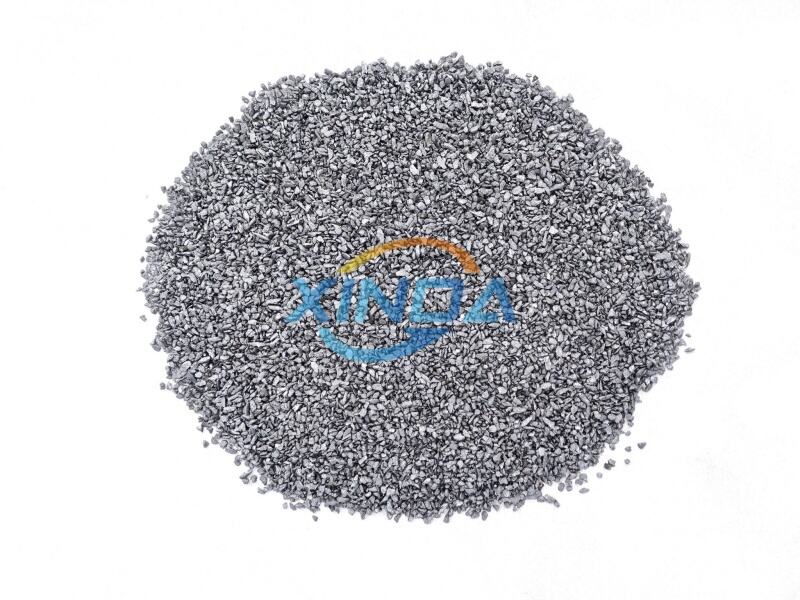

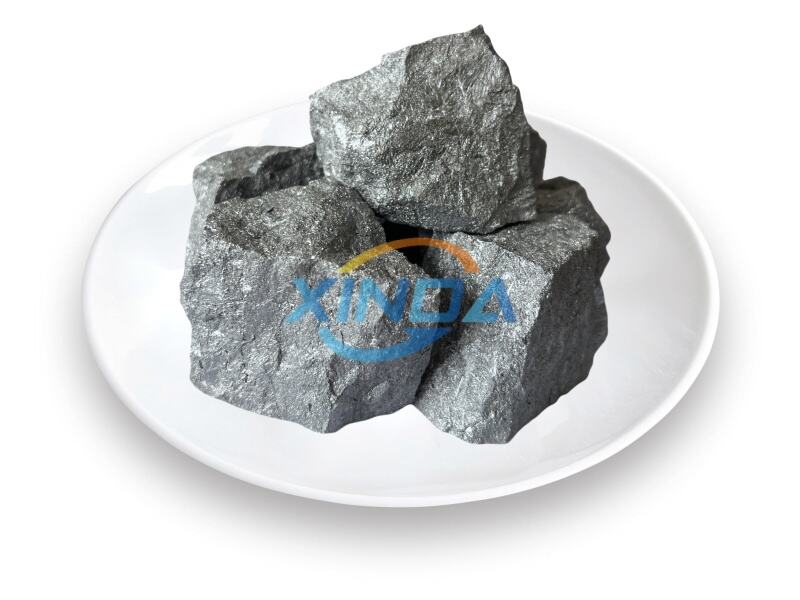

Size: 0-10mm, 10-50mm, 10-150mm or Customized

-

Shape: Natural blocks, Standard blocks, Grain, Powders, etc

-

Sample: Free Sample can be supplied

-

Third-Party inspection: SGS, BV&AHK, etc

-

Using: Cast iron, Steelmaking, Ferroalloy production, Smelting magnesium, etc

- Introduction

- Production Description

- Specification

- Product Processing

- Application

- How to control quality?

Xinda is an enterprise specializing in the production of ferrosilicon in Inner Mongolia. Abundant local mineral resources and electricity at favorable prices. Focus on ferroalloy industry production for more than 25 years, with rich experience. Inner Mongolia is the largest ferrosilicon production region in China, accounting for about 30-40% of the national output.

Production Description

Ferrosilicon is made of iron and silicon with a specific gravity silicon content of 15-90%.

It is widely used in the steel industry, foundry industry, smelting magnesium, and other industrial products.

Specification

Our main products like FeSi75, FeSi72, FeSi70, and Fesi65.

| Ferrosilicon( FeSi) | ||||||

| Grade | Chemical Composition(%) | |||||

| Si | Al | P | S | C | ||

| ≥ | ≤ | |||||

| FeSi75 | 75 | 2 | 0.035 | 0.02 | 0.1 | |

| FeSi72 | 72 | 2 | 0.04 | 0.02 | 0.2 | |

| FeSi70 | 70 | 2 | 0.04 | 0.02 | 0.2 | |

| FeSi65 | 65 | 2 | 0.04 | 0.02 | 0.2 | |

| Packing: 1mt/big bag | ||||||

| Size: 0-10mm, 10-50mm, 10-150mm or according to the client's request | ||||||

| Special FeSi: 1.Low-Titanium FeSi 2. Low Aluminium FeSi 3. Customized | ||||||

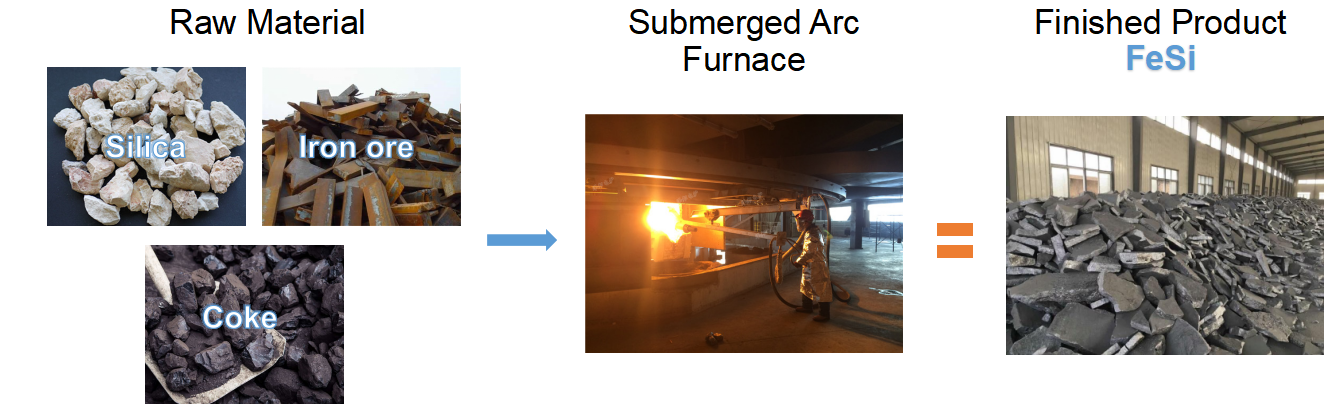

Product Processing

How to produce Ferrosilicon?

The primary raw materials used in the production of FeSi are iron ore, coke, and silica. Iron ore is used as the source of iron, and coke and silica are used as reducing agents. The quality of these raw materials plays a significant role in the quality of the final product.

Iron Ore+Silica+Coke--Submerged Arc Furnace--Finished product FeSi

Application

1. Ferrosilicon is an essential deoxidizer in the steelmaking industry.

In steelmaking, ferrosilicate is used for precipitation deoxidation and diffusion deoxidation. Brick iron is also used as an alloying agent in steelmaking.

2. Ferrosilicon is used as an inoculant and spheroidizer in the cast iron industry.

In the production of ductile iron, ferrosilicon is an important inoculant(to help precipitate graphite) and spheroidizer.

3. Ferrosilicon used in ferroalloy production.

Ferrosilicon 75 is often used in the high-temperature smelting process of metallic magnesium in the Pidgeon process to replace the magnesium in CaO or MgO. Every ton of metallic magnesium produced consumes about 1.2 tons of ferrosilicon.

How to control quality?

Company Testing Report/ Third-Party Inspection

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

AZ

AZ

UR

UR

BN

BN

GU

GU

JW

JW

KM

KM

LO

LO

LA

LA

NE

NE

PA

PA

TA

TA

TE

TE

MY

MY

UZ

UZ

KU

KU

KY

KY

LB

LB

SD

SD