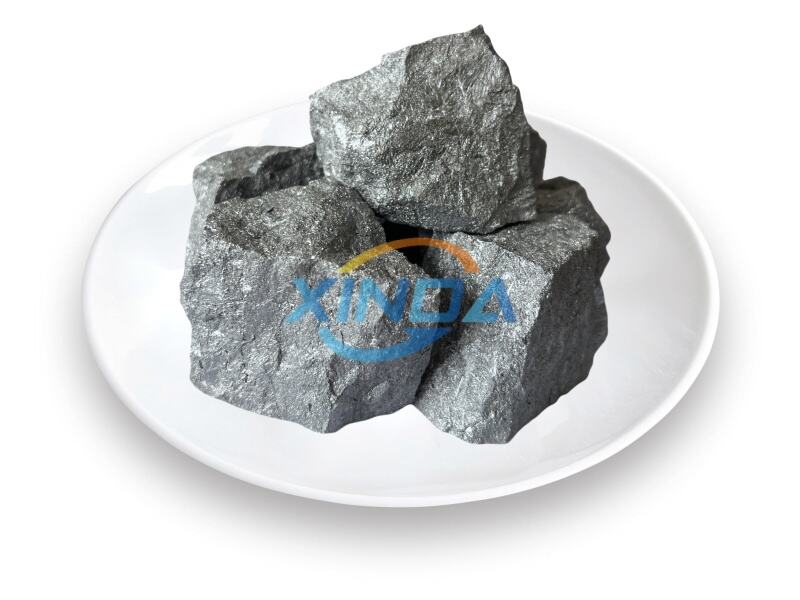

Calcium Silicon

-

Grade: Ca30Si60, Ca28Si55

-

Packing: 1mt/big bag

-

Size: 0-3mm, 3-8mm, 10-50mm or Customized

-

Shape: Standard blocks, Grain/Granules, Powders, etc

-

Sample: Free Sample can be supplied

-

Third-Party inspection: SGS, BV&AHK

-

Using: Cast iron, Steelmaking, Ferroalloy production, etc

- Introduction

- Production Description

- Specification

- Product Processing

- Application

- How to control quality?

Xinda is an enterprise specializing in the production of ferroalloy in Inner Mongolia. Abundant local mineral resources and electricity at favorable prices. Focus on ferroalloy industry production for more than 25 years, with rich experience. Average production and sales of 20,000 tons per month.

Production Description

Calcium silicon is made of silicon, calcium, and iron. Calcium and silicon have a strong affinity with oxygen. Especially calcium, not only has a strong affinity with oxygen, but also with sulfur, and nitrogen have a strong affinity. So the calcium and silicon alloy is an ideal compound deoxidizer and desulfurizer. Calcium silicon alloy is also suitable for converter steel-making workshops as the warming agent, and cast iron's inoculant and additives in nodular cast iron production.

Specification

| Calcium silicon(CaSi) | ||||||

| Grade | Chemical Composition(%) | |||||

| Ca | Si | C | Al | S | P | |

| ≥ | ≤ | |||||

| Ca30Si60 | 30 | 58-65 | 1 | 1.4 | 0.05 | 0.04 |

| Ca28Si55 | 28 | 55-65 | 1 | 1.4 | 0.05 | 0.04 |

| Packing: 25kg/bag, 1mt/big bag | ||||||

| Size: 1-3mm, 3-10mm, 10-50mm, 10-100mm or according to client's request | ||||||

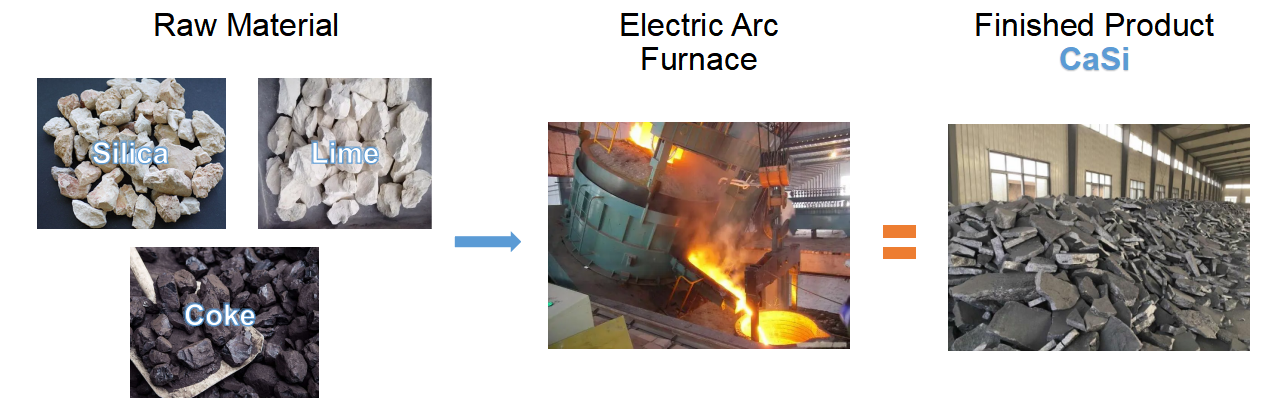

Product Processing

How to product Calcium Silicon?

Silica+Coke+Lime--EAF--Finished product processing

Application

1. Application of calcium silicon alloy in steel metallurgy:

Calcium silicon alloy is an important alloy additive in steel metallurgy. By adding calcium silicon alloy, the toughness and strength of steel can be increased, and the heat treatment properties of steel can be improved. Calcium silicon alloy can also reduce the sulfur content in steel and improve the quality and performance of steel.

2. Application of calcium silicon alloy in the foundry industry:

Calcium silicon alloy is widely used in the foundry industry. It can be used as a deoxidizer and added to casting materials to reduce the oxide content in castings and improve the quality of castings. In addition, calcium silicon alloy can also be used as a rare earth alloy additive for casting materials to improve the mechanical properties and surface quality of castings.

3. Application of calcium silicon alloy in the metallurgical industry:

Calcium silicon alloy is also widely used in the metallurgical industry. It can be used as a desulfurizer to remove sulfur from steel and iron during steelmaking and ironmaking. In addition, calcium silicon alloy can also be used as an alloy additive for smelting alloys to improve the hardness, strength, and wear resistance of the alloy.

4. Application of calcium silicon alloy in the electronic industry:

Calcium silicon alloy also has important applications in the electronic industry. It can be used as a semiconductor material in the manufacture of electronic components, integrated circuits and solar cells. The electrical conductivity and stability of calcium silicon alloy make it an indispensable material in the electronics industry.

How to control quality?

Company Testing Report/ Third-Party Inspection

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

AZ

AZ

UR

UR

BN

BN

GU

GU

JW

JW

KM

KM

LO

LO

LA

LA

NE

NE

PA

PA

TA

TA

TE

TE

MY

MY

UZ

UZ

KU

KU

KY

KY

LB

LB

SD

SD