Silicon Carbide(SiC)

-

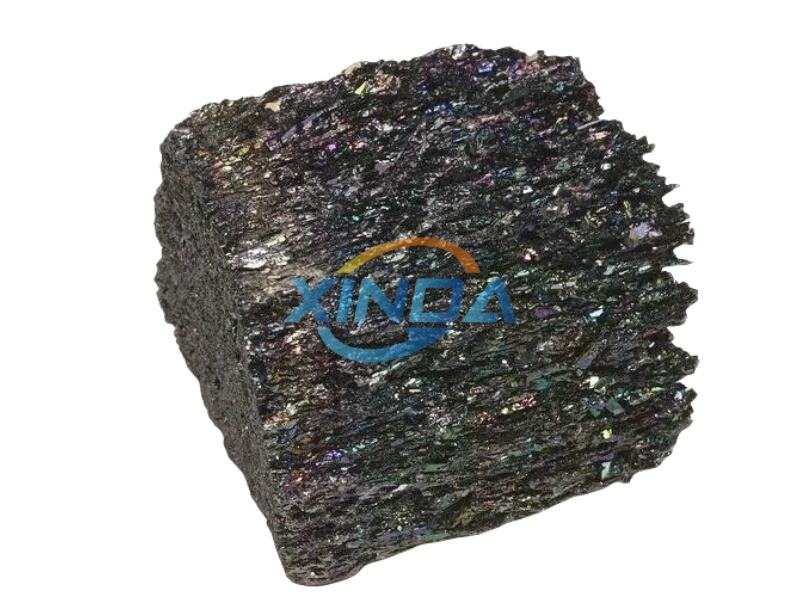

Grade: Black Silicon Carbide, Green Silicon Carbide

-

Packing: 25kg/small bag, 1mt/big bag

-

Size: 0-5mm, 0-10mm, 10-50mm or Customized

-

Shape: Lump, Grain, Powders, etc

-

Sample: Free Sample can be supply

-

Third-Party inspection: such as SGS, BV&AHK

-

Using: Casting, Steelmaking, Refractory, etc

- Introduction

- Production Description

- Specification

- Product Processing

- Application

- How to control quality?

Xinda is an enterprise specializing in the production of ferroalloy in Inner Mongolia. Abundant local mineral resources and electricity at favorable prices. Focus on ferroalloy industry production for more than 25 years, with rich experience. Average production and sales of 5,000 tons per month.

Production Description

Silicon carbide(SiC), also commonly known as Carborundum, is a compound of silicon and carbon. Silicon carbide has high density, high purity, does not pollute liquid steel after use, high recovery rate and stable effect.

Silicon carbide contains two common basic varieties: black silicon carbide and green silicon carbide. Black silicon carbide contains sic about 95%, so the toughness is higher than green silicon carbide. It is widely used for processing low tensile strength material like glass, ceramics, stone, refractory material, cast iron and nonferrous metal etc. Green silicon carbide contains sic about 97% above with good self-sharpening, so it is used for processing hard alloy, titanium alloy and optical glass as well as cylinder jacket and fine grinding cutting tools.

Specification

| Silicon Carbide(SiC) | ||||

| Grade | Chemical Composition (%) | |||

| SiC(min) | Free Carbon(max) |

Fe2O3(max) |

||

| SiC-98.5 | 98.5 | 0.2 | 0.60 | |

| SiC-98 | 98 | 0.3 | 0.80 | |

| SiC-97 | 97 | 0.3 | 1.20 | |

| SiC-95 | 95 | 0.6 | 1.20 | |

| SiC-90 | 90 | 2-10 | 1.2 | |

| SiC-88 | 88 | 5-15 | 3.5 | |

| SiC-85 | 85 | 5-15 | 3.5 | |

| SiC-75 | 75 | 12-15 | 8-12 | 3.5 |

| SiC-70 | 70 | 12-15 | 8-12 | 3.5 |

| SiC-65 | 65 | 12-15 | 8-12 | 3.5 |

| SiC-60 | 60 | 12-15 | 8-12 | 3.5 |

| Packing: 25kg/bag, 1mt/big bag | ||||

| Size: 0-10mm, 1-10mm, 10-50mm or according to client's request | ||||

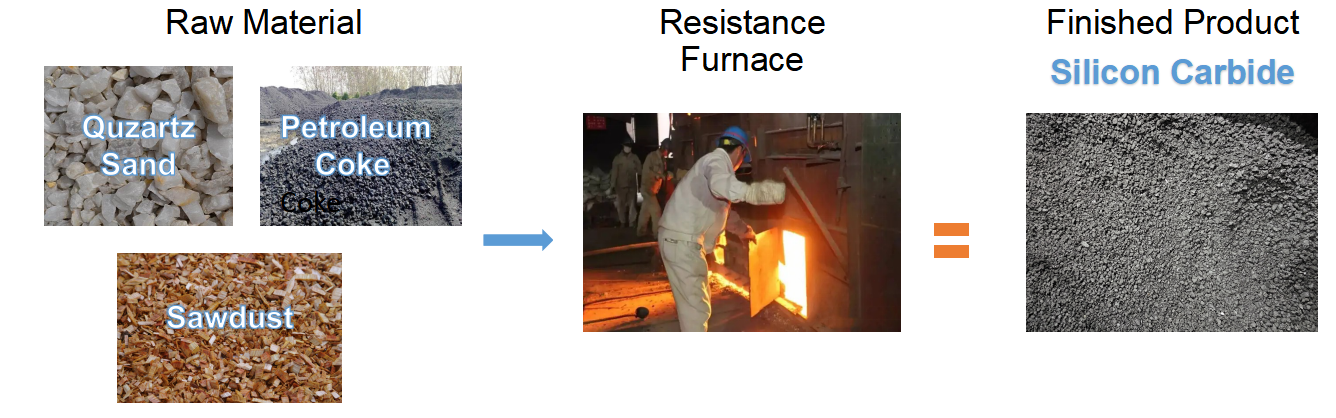

Product Processing

How to product Silicon carbide?

Quzartz Sand+Petroleum Coke+Sawdust--High Temperature Smelting--Finished product processing

Application

Silicon carbide is used as a refractory application in the production of iron, steel, ceramics, nonferrous metals, energy, chemicals, etc.

1. Silicon carbide is used as a deoxidizer in steelmaking.

It can save energy, improve the efficiency of steelmaking, and improve the quality of steel.

2. Silicon carbide is used as a deoxidizer and reducting agent in iron casting.

The use of silicon carbide in cast iron can improve the fluidity of the molten metal, making it easier to fill the liquid metal into the mold in complex shapes, make the cast iron structure compact, and increase the smoothness.

3. Silicon carbide is used as an abrasive, it can be used as a grinding tool, such as the grinding wheel, oil stone, grinding head, sand tile, etc.

4. Silicon carbide High-purity single crystals can be used to make semiconductors and silicon carbide fibers.

How to control quality?

Company Testing Report/ Third-Party Inspection

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

AZ

AZ

UR

UR

BN

BN

GU

GU

JW

JW

KM

KM

LO

LO

LA

LA

NE

NE

PA

PA

TA

TA

TE

TE

MY

MY

UZ

UZ

KU

KU

KY

KY

LB

LB

SD

SD