- Introduction

- Production Description

- Specification

- Product Processing

- Application

- How to control quality?

Xinda is an enterprise specializing in production of ferralloy in Inner Mongolia. Abundant local mineral resources and electricity at favorable prices. Focus on ferroalloy industry production more than 25 years, with the rich experience. Average production and sales of 2,000 tons per month.

Production Description

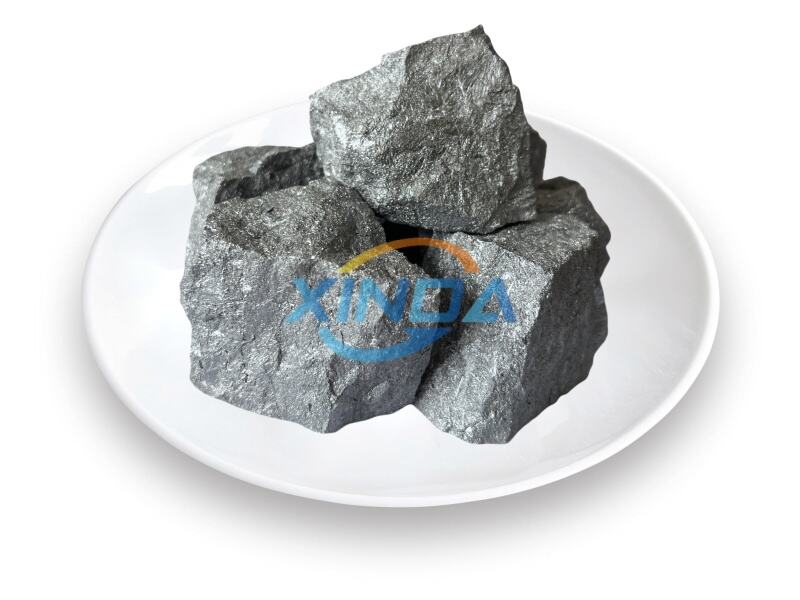

Electrolytic manganese metal flakes are mainly composed of Mn (99.7%-99.9%). They appear as irregular flakes that are firm and crisp. One side is bright while the other is rough. Their color ranges from silvery white to brown.

Manganese can enhance steel's strength, toughness, abrasion resistance, and corrosion resistance. Therefore, it is generally used to produce steel, stainless steel, and non-Steel alloys.

Specification

| Electrolytic Manganese Metal Flakes | ||||||||

| Grade | Chemical Composition(%) | |||||||

| Mn | C | S | P | Si | Se | Fe | ||

| ≥ | ≤ | |||||||

| Mn-99.70 | 99.70 | 0.04 | 0.05 | 0.005 | 0.010 | 0.10 | 0.03 | |

| Packing: 25kg/bag, 1mt/big bag | ||||||||

| Size: 10-50mm | ||||||||

Product Processing

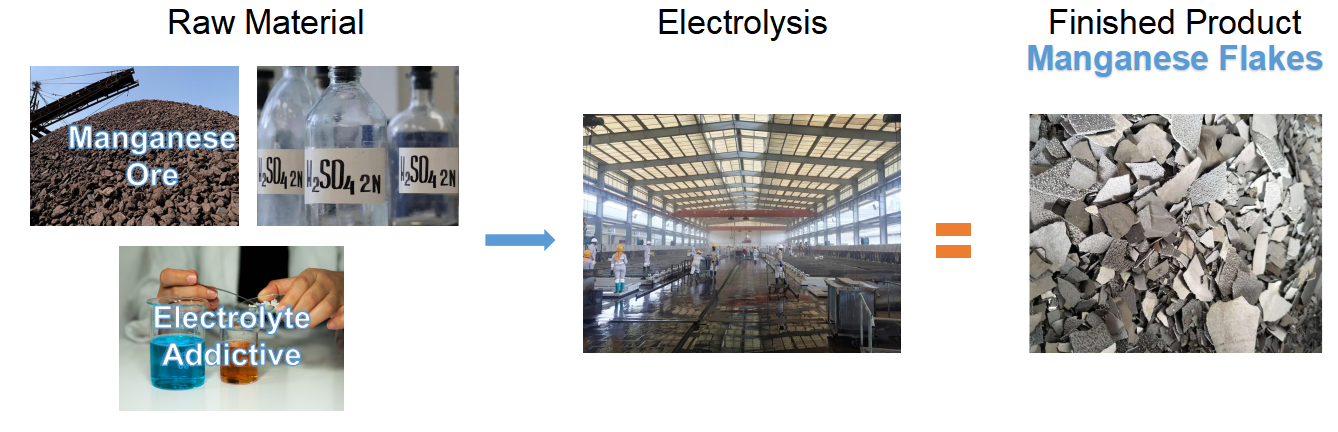

How to produce Electrolytic Manganese Metal Flakes?

There are two main methods of refining manganese metal: thermal method(fire method) and electrolytic method(wet method). The purity of thermal method production(metal manganese) does not exceed 95-98%, while pure metal manganese is prepared by the electrolysis method(Electrolytic metal manganese), its purity can reach over 99.7~99.9%. Electrolytic production has become the main method of manganese metal production. Use manganese carbonate ore powder as raw material. Leach the raw material with sulfuric acid. Obtain a manganese sulfate solution. The electrolytic metal manganese sheet product is produced by the electrolytic method.

Application

Manganese and manganese alloy is one of the indispensable raw materials in the iron and steel industry, aluminum alloy industry, magnetic material industry, and chemical industry.

1. Manganese Metal is an indispensable additive in the smelting industry.

Electrolytic metal manganese processing into powder is the main raw material for the production of manganese tetroxide.

2. Electrolytic manganese metal is used in many industries.

Electrolytic manganese metal due to its high purity, and low impurity characteristics, has been successfully and widely used in iron and steel smelting, non-ferrous metallurgy, electronic technology, chemical industry, environmental protection, food hygiene, electrode industry, aerospace industry, and other fields.

3. The purity of electrolytic manganese is very high, its role is to increase the hardness of metal materials.

The most widely used in manganese copper alloy, manganese aluminum alloy, and 200 series stainless steel. Manganese in these alloys can improve the strength, toughness, wear resistance, and corrosion resistance of the alloy.

Our company adopts an electrolytic melting method to produce manganese, which has the more higher content of Mn, and a lower content of CS and other elements, with the use of a wider range.

How to control quality?

Company Testing Report/ Third-Party Inspection

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

AZ

AZ

UR

UR

BN

BN

GU

GU

JW

JW

KM

KM

LO

LO

LA

LA

NE

NE

PA

PA

TA

TA

TE

TE

MY

MY

UZ

UZ

KU

KU

KY

KY

LB

LB

SD

SD