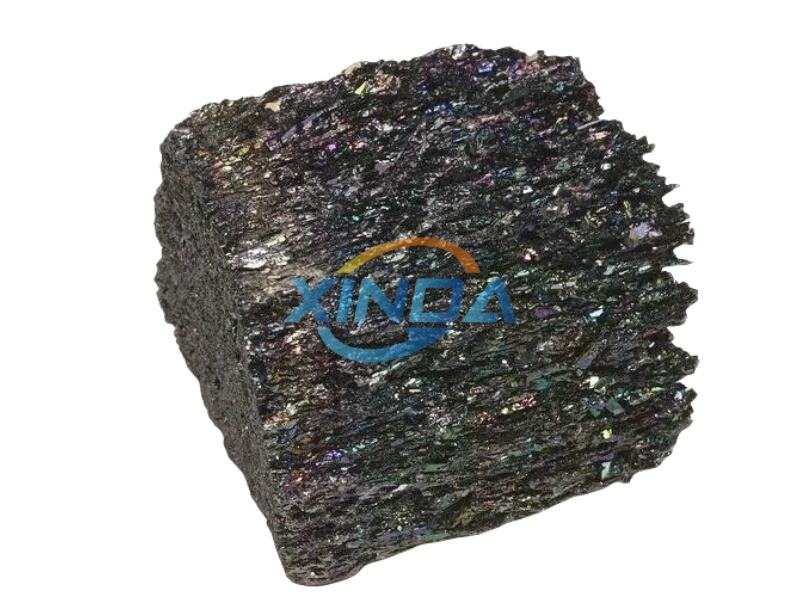

Silicon carbide: Silicon Carbide is a very hard and strong material that can be used in various industrial sectors. It is recognized for its strength and durability. Silicon carbide (like any other ceramics) is actually a “composite”, or not entirely single-phase. A common product will be sintered silicon carbide, which after being subjected to the high temperature process called „sintering“, gains even higher strength than SiC turned out in previous processing stages. In this article, we are going to address what makes sintered silicon carbide so special and how it is prepared as well the applications of use comparing with other materials. Here, we will be going into much more detail about its Benefits Properties Manufacturing Process Applications To Give You Better Insights Into Why It Is So Important.

Because of this sintered silicon carbide comes with a lot of great properties which results into making it useful material in many fields. Maintains strength even under high temperatures. This makes it applicable in environments that other types of materials may melt or degrade. Also, sintered silicon carbide does not easily wear out, giving it outstanding operational longevity even under malignant conditions. They are non-corrosive and will not rust, which makes them an ideal material for use where moisture is a problem.

It can also carry heat very well. This allows sintered silicon carbide to be very valuable on a molecular level in devices that require flexible heat management, such as those utilized in electronics. Also, the melting point of sintered silicon carbide is very high and thereby they cannot be avoided. These and many other amazing features have made it an ideal choice for a wide range of applications across various industries like aerospace, electronics, defense etc.

Sintering (the word sinter comes from the German verb of "sintern") is actually a kind of special process in which you heat up your material until it starts melting and getting stuck together. This is what makes sintered silicon carbide unusually strong compared to regular old silicon carbide. These particles bind together less tightly but very closely when the material is heated up during sintering. The bonding process results in a denser finished product, so there are less gaps or holes in the material. This makes it less vulnerable to cracking or breaking, even when subject to high pressure. One of the most important steps for improving the quality and stability of a silicon carbide is sintering.

Sintered silicon carbide is also a valuable material with many specific manufacturing steps involved in production. The first is using silicon carbide powder mixed with a special binder that keeps the whole thing together. Then this blend is dried to formic the required shape with friendly device called press This is pressed onto the Mrs with a lot of force. This pressure is necessary as it will make the end result bolder and more intense.

Another vital application of sintered silicon carbide is electronic devices. It is also used as a heat sink in various electronics due to its high thermal conductivity. Electronic components become hot and to keep them functioning heat sinks are necessary. And, it is a common material used in high–powered electronics as well due to its ability of maintaining performance at very hot temperatures and not degrading or mechanical breaking easily.

On comparison of sintered silicon carbide with other materials and particularly in the area of high temperature performance it displays a host if advantages over them. For example, it is stronger and tougher than ceramics such as alumina or zirconia. It thus means that it can withstand more loads and weight without cracking. Furthermore, sintered silicon carbide has a higher thermal capacity than hard materials. For this reason, it is usually selected for applications that contain high temperatures and mechanical stresses.

Xinda manufacturer concentrates on silicon series such as ferrosilicon. calcium silica and ferro silicon magnesium. chrome, high carbon silicon, silica slag, and so on. warehouse has around 5,000 tones. long-term relationships with various steel mills distributors both locally overseas. Covering more than 20 countries regions across the globe, which includes Europe, Japan, South Korea, India, and sintered silicon carbide.

Xinda certified by ISO9001, SGS and other certification. have advanced and sintered silicon carbide chemical inspection analysis equipment, and standardized analysis methods provide an assurance objective production top-quality product. Strict inspection and control the incoming flow raw materials. Make pre-production, production, final random inspection. accept third-party SGS, BV, AHK).

Xinda Industrial professional ferro alloy manufacturer, situated key iron ore production zone, benefit from unique resource advantage. Our company occupies total area 30,000 square meters with registered capital of 10 million RMB. Established over 25 years ago and has four sintered silicon carbide-arc furnaces, and four refinement furnaces. earned trust of our clients during ten years of exporting.

Xinda over 10 years of experience sintered silicon carbide experienced team that can offer professional products for customers. offer every kind customized, like special requirements, sizes, packing etc. state-of-the-art production equipment together with our secure logistic system, ensures a smooth timely delivery final destination.