Have you heard of SiC silicon carbide? Seems like a big and fancy word, but actually it influences our lives in a lot of aspects. SiC is a rather special material that has been used in semiconductors for many years, but most notablly within the technology of SiC silicon carbide itself. And it is becoming more and more popular in our day to day life over time. So, let's take a look into what SiC silicon carbide really is.. how it works and amazing ways its altering technologies as we know them!

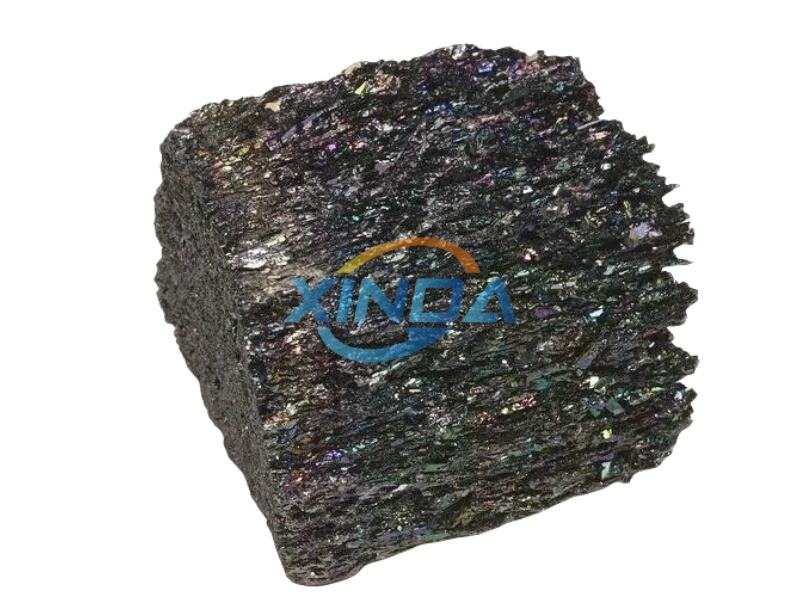

Silicon Carbide SiC, a compound of two key elements namely; silicon and carbon. These materials combine to make an extremely hard, tough material. This material is most commonly used in the creation of airplanes and cars among others industries. In SiC silicon carbide is a material that has found its place in technology as it provides some unique properties which are beneficial for many applications, especially after more and more open circuit.

SiC silicon carbide technology is one of the most exciting developments in modern tech. ENLARGEHow they work: Electronic devices one way and a very big one in its own right—of lessening energy use is to simply make electronic devices that perform more efficiently (e.g., your mobile phone wasting fewer watts). SiC silicon carbide has a higher electrical conductivity than the common materials such as that of Si. Basically, devices built with SiC (silicon carbide), then can handle more power while running cooler. It is particularly relevant for devices such as smartphones and computers, which have to run efficiently while still remaining cool.

Renewable Energy To be more sustainable, next big thing different is using SiC silicon carbide to increase capacity and make devices better. It is used in tech like solar panels and wind turbines because it can withstand massively high temperatures, as well as being radiation- and heat-hardy. As a result, renewable energy systems built with SiC silicon carbide are not only longer-lasting but more efficient too. This will also help to decrease our carbon footprint and promote sustainable energy.

The second major benefit is its electronic conductance. The SiC silicon carbide is an order of magnitude superior electrical conductor than conventional materials. What this means in practice is that SiC silicon carbide devices can handle more electrical power and they do so much better when it comes to their energy consumption. Being able to run as efficiently and powerfully as possible is imperative for electrical devices like smartphones, computers (and of course) your local lighting provider.

Versatile Material of SiC Silicon Carbide It is often used in the automotive industry to manufacture heavy-duty components for vehicles, among other things. The element is also used in renewable energy applications, such as solar panels and wind turbines because it has a high melting point — meaning that temperature doesn't have much of an effect on the integrity of Neodymium composition structures – -and resists to corrosion from heat and radiation.

Another application of SiC silicon carbide is the medical area where components safe for the human body are made. This means that the parts will not do us any harm or cause any negative reactions when we come into contact with them. The aerospace industry also applies SiC silicon carbide to develop parts capable of surviving high temperatures and radiation, which is necessary for the safety and running of things in the area. With numerous uses, SiC silicon carbide is a vital material for industries in multiple disciplines since it helps better products and technologies. Industry Changes Brought by SiC Silicon Carbide SiC silicon carbide is a revolutionary material changing numerous industries. In the automotive area, the material helps in creating stronger and safer car components, which eventually creates more efficient and reliable vehicles. The electronic area also utilizes SiC silicon carbide to develop more powerful and energy-efficient devices. Thus, the innovation enhances our lives in various ways by providing modern technology to keep the world connected and updated. For example, it makes smartphones work and remain charged for long, creating a better and more comfortable user experience. In the renewable energy industry, the material helps in creating more efficient and durable systems vital for ensuring that its products remain green. The material also finds application in the medical and aerospace industries, making it an essential material to our daily life.

Xinda Industrial professional ferro alloy manufacturer, situated key iron ore production zone, benefit from unique resource advantage. Our company occupies total area 30,000 square meters with registered capital of 10 million RMB. Established over 25 years ago and has four sic silicon carbide-arc furnaces, and four refinement furnaces. earned trust of our clients during ten years of exporting.

Xinda are a company more than 10 years of experience exporting. experienced team that can offer professional sic silicon carbide customers. provide all kind custom made, including special requirements, sizes, packing and more. are equipped with a full set advanced production equipment and the secure logistic system guarantees quick smooth delivery to final location within agreed upon time.

Xinda accredited by ISO9001, SGS other certification. We have modern and thorough chemical inspection and analysis equipment tested analytical methods offer an objective guarantee the production of high-quality products. Strict sic silicon carbide inspection and control raw materials. Make pre-production, during production and after the final random inspection. We offer third-party SGS, BV, AHK).

Xinda is manufacturer, mainly focus silicon series products, such ferrosilicon calcium silicon, ferrosilicon magnesium, ferro chrome, high carbon silicon, silicon slag, etc. warehouse usually around five thousand tons stock. have long-term sic silicon carbide with variety steel mills and distributors, both domestically internationally. global reach includes more than 20 countries including Europe, Japan South Korea India and Russia.