Onsemi silicon carbide allows power semiconductor market, one of the most important materials This market is involved with the production of systems used for controlling and converting electricity. Onsemi silicon carbide is one of those options, and it has a huge number of advantages that highlight its utility. This article will discuss the advantages of Onsemi silicon carbide technology, how it is accelerating power semiconductor industry to new levels, why this can explain as a future for energy management and what are applications which using strong but heavy on need in lots of Power.

Benefits of Onsemi silicon carbide technology This attribute makes it useful for applications that require high heat handling capabilities. It means that it can be used very well in the hot places and there is no chance of breaking or any kind damage. For instance; In high temperature factories or power plants, Onsemi silicon carbide can still work efficiently. It also loses less energy operating in this mode. This quality saves energy and improves device performance in this way. Furthermore, Onsemi silicon carbide is very durable and has a longer lifespan than traditional polypropylene materials so that it can be used in various sectors too. This makes it very suitable for the power semiconductor industry because of its imperviousness and strength over time.

Onsemi silicon carbide does this a lot different than traditional methods, which is why so many people are buzzing about it. This means it is increasing efficiency of the process and making everything better for everyone. One way it accomplishes this, is by optimizing power management. Better power management can also turn out to save energy, which is good for the environment. And that in turn means less pollution, a more sustainable planet. In addition, Onsemi silicon carbide technology is reducing the size and ease of use. Therefore, the lives of individuals who require these devices may be made easier by allowing them to find such facilities on a more accessible basis.

THDshapes Semiconductor silicon carbide is the so-called future of power management since there are many such advantages over others that employed today. The other main benefit is it thrives in high heat capacities so you are able to put this pipe into very hot areas and not have much of a worry. A second great advantage: strict energy efficiencies, and which implies that they can save more energy in work than other materials. For many uses this efficiency is key. Furthermore, Onsemi provides you silicon carbide which is extremely robust and have a long-life service time that makes it viable for large industries.

In terms of high power needs, Onsemi silicon carbide offers numerous solutions. An example of this is its high-voltage gate drivers. Not only do these units control the energy allocation more precisely, but it can also save you some money and make your HVAC system work in an optimal condition. In an electric car, high-voltage gate drivers are essential components to efficiently manage power. Under the arrangement of diode rectifiers is a different solution. These components find their uses in various sectors including electric vehicles, solar power systems,... They are also used in many other industries, which makes diode rectifiers a very viable option across the board.

Onsemi SiC technology is unique and innovative. This device is exclusively made to work regarding efficiency and energy saving, it helps in conservation of more needed electricity nowadays. Plus, it is highly durable and long-lasting. The technology provided by Onsemi has the unique thing that high-voltage gate drivers are used. Such drivers help in addressing the energy consumption issues more efficiently thereby ensuring better savings on energy. The diode rectifiers are another important aspect that is used in majority of applications and industries. This is a major value differentiator that makes Onsemi silicon carbide more competitive in the power semiconductor market.

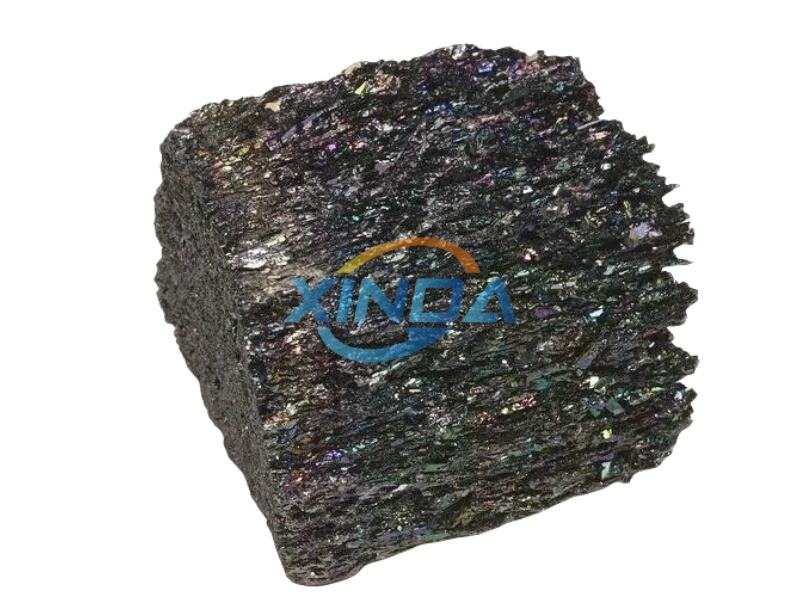

Xinda accredited by ISO9001, SGS other certification. We have modern and thorough chemical inspection and analysis equipment tested analytical methods offer an objective guarantee the production of high-quality products. Strict onsemi silicon carbide inspection and control raw materials. Make pre-production, during production and after the final random inspection. We offer third-party SGS, BV, AHK).

Xinda a manufacturer, mainly focus onsemi silicon carbide series products, such ferrosilicon and calcium silicon, ferro silica magnesium, ferro chrome, high carbon silicon, silicon slag, etc. Our warehouse is usually stocked with around 5,000 tons inventory. have long-term partnerships with numerous steel mills, distributors, both locally as well as overseas. global reach covers more than 20 countries, including Europe, Japan South Korea India and Russia.

Xinda over 10 years of experience onsemi silicon carbide experienced team that can offer professional products for customers. offer every kind customized, like special requirements, sizes, packing etc. state-of-the-art production equipment together with our secure logistic system, ensures a smooth timely delivery final destination.

Xinda Industrial a professional ferro alloy manufacturer, situated in key iron ore onsemi silicon carbide zone, we benefit from unique resource advantage. Our facility covers space 30,000 sq meters with registered capital of 10 million RMB. Established for over 25 years, company home to four submerged arc furnaces four refinery furnaces. have over 10years export experience have earned the trust of its customers.