Green silicon carbide is a non-metallic mineral. It worked, but it was built differently from the typical form of silicon carbide. This unique green color is the result of a specific process. That green comes from additional carbon and chromium it sees during production. Green silicon carbide, which is hard and granular in nature helps to be used widely.GREEN SILICON CARBIDE USED IN CUTTING COOLERазв Green Silicon Carbide It's used in construction, electronics and manufacturing.

Green Silicon Carbide is just one of the many materials that Steel Flattening Media can compete with and actually out perform. One of the main benefits is that it has great hardness and strength. In other words, it can be used in conditions that would wear out or may break materials. For instance, the metal is perfect for multiple uses given its ability to resist heavy wear and high temperatures in construction.

Another more interesting fact about green silicon carbide is that it 's quite lightweight. The weight of concrete is the same, but it does not have that added bulk.This ability to be lightweight can concretfronsanchorvomosof probably its biggest advantage over sand and other forms. It means using lighter materials that enable more efficient fuel consumption and lower energy usage. It also has a very high strength-to-weight ratio, making it ideal for constructing structures like buildings and bridges. Green silicon of this kind can help in creating safe structure as well.

Both silicon compounds are revolutionizing several industries, including manufacturing and green silicon carbide. This is used in factories to create highly durable & heat-resistant light-weight products. This, in turn, gives manufacturers the ability to make items more environmentally friendly as well. Some companies can use this material to lower harm on the planet while still distributing high-quality products.

Green silicon carbide is an essential element in manufacturing of more efficient and environmentally friendly electronic components. These properties make it possible to produce more efficient devices that consume less electricity. In other words, electronics are becoming more environmentally friendly and their users like that. Consumers are demanding for eco solutions, hence it's possible to now manufacture items that helps save the world and green silicon carbide was born.

Because of its special properties, green silicon carbide has become the leader in many fields. This produces a strong, light weight product that is able to withstand high heat and wear. TEDThis allows industry to produce products that are not only efficient, but environmentally friendly. When you choose green silicon carbide, your companyis equipped to deliver the high-quality products that meetcustomer demands and be kindto our environment.

Also, green Silicon Carbide is utilized in the construction of better and greener electronic parts. Therefore, this paradigm shift really is needed to create devices that are friendly for the environment and can help prevent waste… plus save energy. Some potential customers of green silicon carbide are eco-aware and want products that help make the planet a little bit healthier.

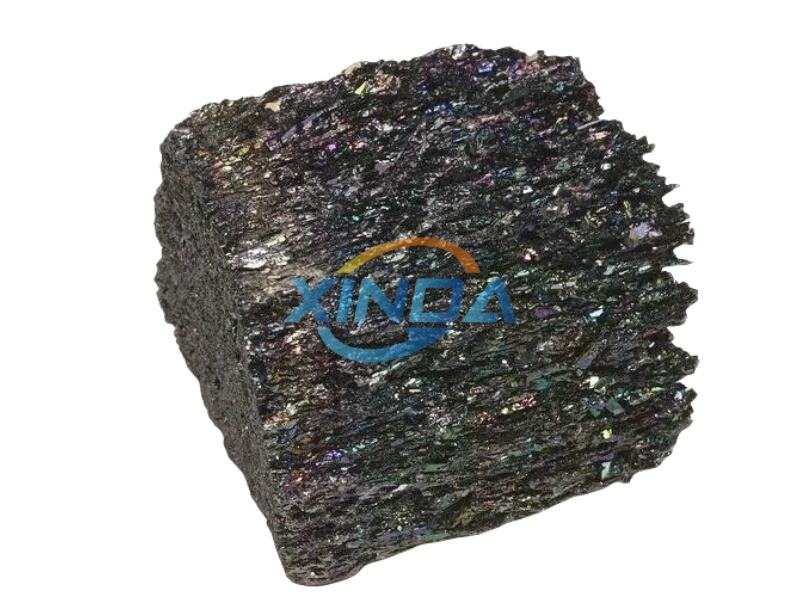

Xinda Industrial a professional ferro alloy manufacturer, situated a key iron ore production zone, benefit from unique resource advantage. company covers an area of 30,000 square meters with a registered green silicon carbide of 10 million RMB. Established since 1995, company four submerged arc furnaces, as well as four refinery furnaces. have more than 10 years export experience, have won trust of customers.

Xinda accredited by ISO9001, SGS other certification. We have modern and thorough chemical inspection and analysis equipment tested analytical methods offer an objective guarantee the production of high-quality products. Strict green silicon carbide inspection and control raw materials. Make pre-production, during production and after the final random inspection. We offer third-party SGS, BV, AHK).

Xinda over 10 years expertise in exporting offer expert services to customers. offer a wide range customized products including special requirements sizes, packaging, etc. modern production equipment, along with safe green silicon carbide system assures efficient and prompt delivery to final destination.

Xinda is manufacturer is primarily focused on the silicon series, like ferrosilicon, calcium silica ferro silicon magnesium, ferro chrome, high carbon silicone, silicon slag, etc. warehouse holds approximately five thousand tons. have long-term relationships numerous steel mills, distributors, both locally as well as internationally. global reach green silicon carbide more 20 countries, including Europe, Japan South Korea India Russia.