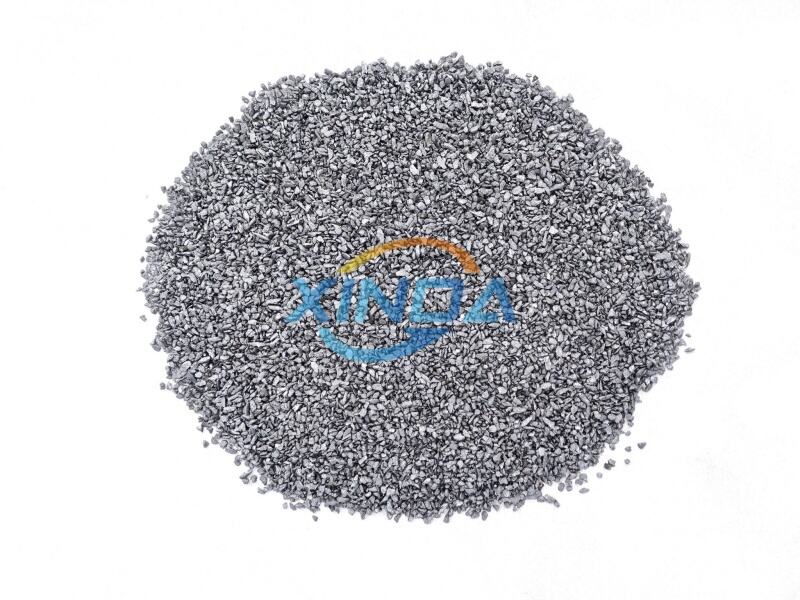

There are various ways in which a unique type of metal, the Ferrosilicon can assist. A combination of two essential ingredients that are: iron and silicon. When mixed together these two metals combine to create ferrosilicon, which is a strength amalgamation able of enduring and resisting the effects associated with rust. With all of these wonderful properties, it is evident why ferrosilicon finds widespread uses for many factories and industries communities.

Pebbles are compounds that contain two or more types of metal. With these two used in conjunction, they function better together than individually. An example of an alloy is steel. It is non-metal crafted from iron and carbon. In the manufacture of many of those alloys, ferrosilicon is a key component. Researchers and engineers are continuously exploring different methods to further enhance the power of alloys. They also create these by mixing larger with smaller batches of various metals (sometimes they combine them with other materials as well) to produce a whole new type of alloy, which can perform even better in its specialized applications.

If there is a material that we humans use dreadfully frequently it would be steel. We use steel for many things: cars, buildings and machines. Actually, ferrosilicon is the important ingredient in making steel. Steel is what you get after iron has been melted and combined with carbon, along side other materials. During this process, ferrosilicon is also added because it apparently plays a role in removing impurities from the iron and giving us that super tough indestructible steel. In fact more than 90% of all ferrosilicon produced across the world is in turn used by the steel industry, which just goes to show how necessary it really is for producing this essential material.

Metal casting was a pretty cool way to make things. That is where it gets a casting, melting the metal and pouring hot liquid into shape as will solidify. We have been using this approach for making tools and attractive jewelry since thousands of years. Also ferrosilicon as an additive to a molten base iron so that his sentence from another element while ensuring the doping and its function in casting is not adrift of the temperature generated during melting. It is far easier to deal with during casting. Moreover, it helps in lowering the contaminants of the metal and hence a stronger, more durable end product.

Because of its many benefits, ferrosilicon is employed in several factories. It is strong, durable or rust-resistant so perfect for machinery and equipment In addition, ferrosilicon is an excellent electricity conductor and hence helps in the manufacturing of electrical objects. This is key because certain products like electrical parts that manufacturers are unable to prevent from experiencing erosion, hence this will allow the manufacturer in energy storage development. In addition to which, ferrosilicon is a relatively low-cost and malleable material too, making it desirable among those who need efficient yet affordable substances for their manufacture.

Ferrosilicon is also utilized in a variety of other industries. For example, it is used to produce aluminum alloys necessary for aircraft and other lightweight materials. These aluminum alloys have been included in this list for the aviation sector, as weight plays an important role here. Silicon: Ferrosilicon is also an important component in the production of silicon used to make computer chips and other high-tech electronics. This means we use some form of ferrosilicon in the technology that surrounds us daily. Lastly, ferrosilicon is also used in fertilizers that boost crop growth and improve soil quality to support agriculture.

Xinda Industrial professional ferro alloy manufacturer, situated key iron ore production zone, benefit from unique resource advantage. Our company occupies total area 30,000 square meters with registered capital of 10 million RMB. Established over 25 years ago and has four ferrosilicon products-arc furnaces, and four refinement furnaces. earned trust of our clients during ten years of exporting.

Xinda over 10 years' experience in exporting provides professional services customers. ferrosilicon products all kinds of custom products which include special needs such as size, packaging and so on. equipped with most comprehensive set modern production equipment and secured logistic system which assures a speedy and efficient delivery to desired destination within specified time.

Xinda manufacturer concentrates on silicon series such as ferrosilicon. calcium silica and ferro silicon magnesium. chrome, high carbon silicon, silica slag, and so on. warehouse has around 5,000 tones. long-term relationships with various steel mills distributors both locally overseas. Covering more than 20 countries regions across the globe, which includes Europe, Japan, South Korea, India, and ferrosilicon products.

Xinda certified by ISO9001, SGS and other certification. have advanced and ferrosilicon products chemical inspection analysis equipment, and standardized analysis methods provide an assurance objective production top-quality product. Strict inspection and control the incoming flow raw materials. Make pre-production, production, final random inspection. accept third-party SGS, BV, AHK).