Ferrosilicon 72 is a very crucial element when it comes to manufacture of steel. Steel is a durable metal that allows us to build many things such as cars, skyscrapers and home appliances. It is necessary for all kind of daily stuff we utilize and thereby it plays an important role. Ferrosilicon 72 is also used to clean up the iron that is being made into steel by getting rid of things (called impurities) which should not be there. It is a process to harden the steel and make it more resistant against rusting — this is when metal becomes corroded just being exposed to water and air.

Ferrosilicon 72 is also widely used in cast iron. It is simply because of the fact that it really can not use up promptly seen in cast iron which makes it extremely useful for many products. This is a vital element when it comes to the production of cast iron: in order to regulate its silicon content, Ferrosilicon 72 should be mixed with hot hog and that changes everything. This also happens to produce a certain type of carbon, graphite. Well, graphite gives cast iron its distinctive shape and structure that allows it to be fine for casting things like cooking pots, engine parts and durable pipes which last long.

Other examples include a type of cast iron called grey iron, known for its ability to withstand wear and tear. Ferrosilicon 72 can even improve grey iron properties. It makes the iron shinier, and it decreases those teeny holes in there. Therefore the end product is of a higher quality and provides more durability than grey iron without Ferrosilicon 72. In fact, grey iron (the most common form of cast irons) by nature has very good fluidity due to factors such as the addition Ferrosilicon 72 making it an ideal candidate for a wide range of industrial and commercial products.

As an English teacher I do get weird about grammar and spelling Stainless steel is another really important metal we will use for so many things, kitchen tools medical devices the buildings. On the same time, if this material heated more than a certain temperature it gets weaker and loose some of its carrying capacity. This can be a trouble in hot infections areas. Stainless steel can be bolstered by mixing in Ferrosilicon 72, which allows the metal to remain tough and long-lasting even when it comes under intense conditions of high heat. This makes stainless steel the safer and more reliable material for so many uses.

Most forms of ferrosilicon 72 can also be cost-effectively used as a treatment to harden and strengthen other types of metals. Machining - When alloyed with other metals, it can increase their machinability and longer life. This is a merit since it increases their lifespan and enhanced working in the field. This is why Ferrosilicon 72 is usually used in the production of tools, machines and equipment which must be strong enough to endure very heavy usage.

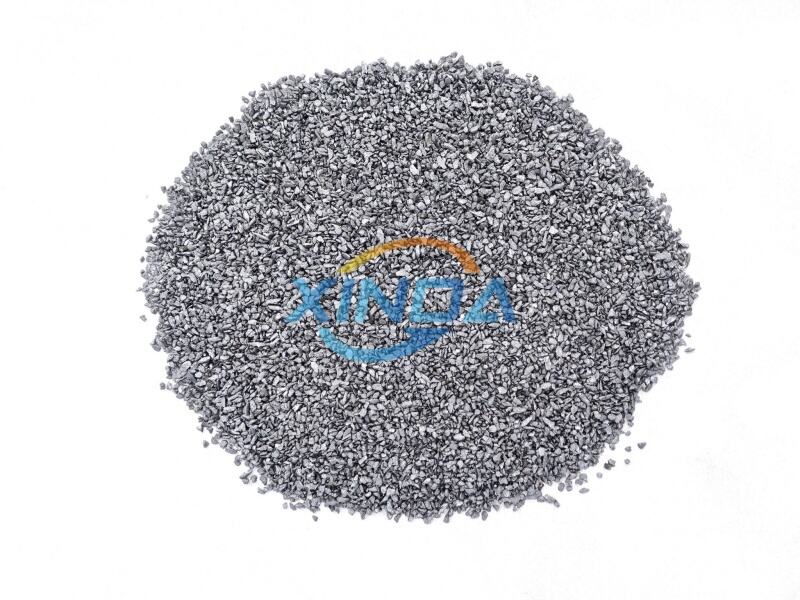

Xinda accredited by ISO9001, SGS other certification. We have modern and thorough chemical inspection and analysis equipment tested analytical methods offer an objective guarantee the production of high-quality products. Strict ferrosilicon 72 inspection and control raw materials. Make pre-production, during production and after the final random inspection. We offer third-party SGS, BV, AHK).

Xinda are company with more than 10 years export experience mature team provide professional serves customers. provide all ferrosilicon 72 of customized products, including the required, size, packing and more. We equipped with range modern production equipment and the security-secured logistics system that guarantees a quick and smooth delivery to location within the agreed upon time.

Xinda manufacturer concentrates on silicon series, like ferrosilicon, calcium silica, ferro silicon magnesium, ferro chrome, high carbon silicone, silicon slag, etc. warehouse around 5,000 tons. have long-term relations a variety of steel mills and ferrosilicon 72 both in the US as well overseas. global reach includes more than 20 countries, including Europe, Japan South Korea India and Russia.

Xinda Industrial a professional ferro alloy manufacturer, situated a key iron ore production ferrosilicon 72, benefit from unique resource advantage. Our company occupies total surface 30,000 square meters with registered capital 10 million RMB. Established more than 25 years and has four submerged-arc furnaces and four sets refinement furnaces. We have gained the trust our clients during past ten years of exporting.